Pallet wrapping machine repair for better packaging results

Wiki Article

Discover the Necessary Benefits of Using a Pallet Wrapping Device in Your Storage Facility Operations

In modern-day storehouse operations, the fostering of pallet Wrapping machines is ending up being increasingly crucial. These devices enhance the packaging process, boosting performance while considerably lowering labor costs. They likewise guarantee regular Wrapping high quality, which is necessary for item protection throughout transportation. However, the advantages prolong past just these facets. There are extra advantages that can transform storage facility management, making it rewarding to explore further.Improved Efficiency in Product Packaging Workflow

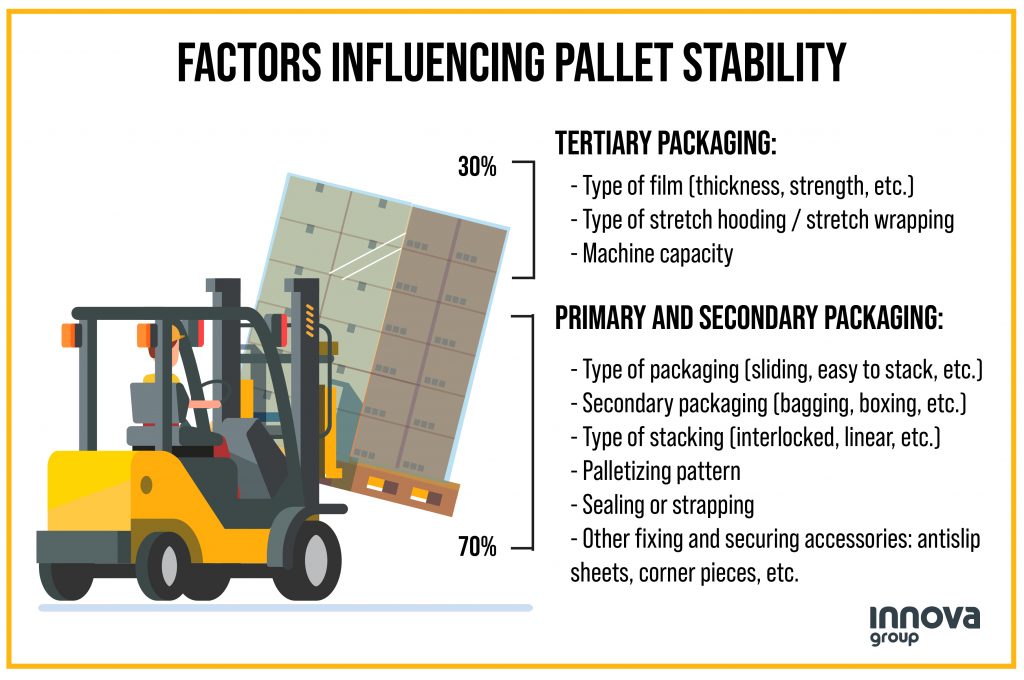

In the domain name of logistics, efficiency stands as a vital goal, and pallet Wrapping devices significantly add to achieving this goal. These machines simplify the product packaging process by automating the Wrapping of items, making certain that items are securely packaged with minimal hand-operated treatment. By minimizing the moment invested on Wrapping, services can enhance their process, enabling quicker turnaround times and enhanced throughput. Additionally, pallet Wrapping equipments give constant Tension and insurance coverage, boosting the security of items throughout transport. This dependability lessens the danger of product damages, which can lead to expensive delays. Generally, the integration of pallet Wrapping makers into product packaging operations fosters a much more reliable, trustworthy, and arranged method to logistics monitoring.Significant Labor Cost Cost Savings

While business seek to minimize operational costs, the fostering of pallet Wrapping machines can lead to considerable labor price savings. By automating the Wrapping process, these devices lessen the demand for hand-operated labor, allowing employees to focus on more crucial jobs. With the capacity to wrap pallets swiftly and continually, fewer employees are required to finish product packaging operations, resulting in reduced payroll expenses. Additionally, the makers boost efficiency as they can operate continually, lowering downtime associated with hands-on Wrapping. pallet wrapping machine repair. This effectiveness converts to faster turnaround times and improved general workflow. Training employees to operate these devices generally calls for much less time compared to training for manual Wrapping techniques, better adding to reduced labor costs in storehouse operations.Enhanced Item Protection During Transportation

Consistent and Reputable Wrapping Quality

Pallet Wrapping machines deliver regular and reliable Wrapping top quality, guaranteeing that every pallet is wrapped evenly regardless of driver experience. This uniformity decreases the threat of damages throughout transport, as effectively wrapped pallets preserve their honesty. The machines apply an excellent amount of stretch film, minimizing waste and making sure that the load is safeguarded successfully. Unlike manual Wrapping, which can differ substantially based upon the worker's strategy, an automatic procedure assurances that each pallet gets the exact same level of protection. This integrity not just boosts Learn More the safety and security of products however likewise improves procedures, enabling a more reliable operations. Ultimately, the consistent Wrapping high quality given by these machines brings about improved client satisfaction and lowered prices connected with product loss.Increased Storehouse Space Use

Effective warehouse room utilization is a critical consider enhancing operations, and pallet Wrapping machines play a significant duty in achieving this goal. By securely Wrapping pallets, these devices minimize the threat of item damages throughout storage and transportation, permitting much more effective piling and storage space techniques. Enhanced stability implies that pallets can be packed greater without endangering safety and security, which optimizes vertical room usage. Additionally, the regular Wrapping procedure guarantees consistent measurements, enabling far better organization and reliable usage of readily available space. This results in minimized aisle size requirements and permits for even more item to be kept in the same location. On the whole, utilizing a pallet Wrapping machine boosts area effectiveness, adding to structured storage facility procedures and enhanced performance.Frequently Asked Concerns

What Kinds of Products Can Be Wrapped Making Use Of a Pallet Wrapping Machine?

Various products can be covered using a pallet Wrapping equipment, consisting of boxes, pallets of food, industrial items, and breakable things. The maker accommodates diverse shapes and sizes, making certain safe packaging for effective transport and storage space.

Exactly how Much Does a Pallet Wrapping Device Typically Cost?

The expense of a pallet Wrapping maker typically ranges from $3,000 to $20,000, relying on functions and capabilities. Factors such as automation level and brand name credibility can substantially affect the final price.Can Pallet Wrapping Machines Be Integrated With Existing Storage Facility Systems?

Pallet Wrapping equipments click here for more info can frequently be incorporated with existing storage facility systems, improving efficiency (pallet wrapping machine repair). This assimilation allows for structured operations, improved stock administration, and better control with other automated procedures, eventually maximizing general warehouse capabilityWhat Is the Upkeep Requirement for Pallet Wrapping Machines?

visit The maintenance demands for pallet Wrapping makers typically include normal assessments, lubrication of relocating components, and substitute of worn parts. Sticking to these methods warranties peak efficiency and durability, lessening operational disturbances in warehouse setups.Exist Security Concerns When Utilizing Pallet Wrapping Machines?

Security problems when making use of pallet Wrapping makers consist of potential injuries from moving components, improper handling, and poor training. Making certain appropriate safeguards, routine maintenance, and worker education and learning can considerably reduce these threats in stockroom environments

Report this wiki page